Each department tracks its conversion costs in order to determine the quantity and cost per unit (see TBD; we discuss this concept in more detail later). Conversion costs are restricted to direct labor and manufacturing overhead, which are needed to convert raw materials into completed products. Prime costs are the direct labor and direct materials costs incurred to build a product. In simpler terms, direct labor costs are the payments to the workers doing the hands-on work, while manufacturing overhead costs are the behind-the-scenes expenses that keep the entire production process going. Both are essential components of conversion costs, giving a complete picture of the money spent to transform raw materials into finished products. In the table above, the direct labor costs and manufacturing overhead for Company XYZ are listed along with their respective amounts.

For example, if the direct labor cost is $50,000 and the manufacturing overhead cost is $40,000, the total conversion cost is $90,000. In this section, we will delve into the concept of the conversion cost ratio and its significance in cost accounting and management. The conversion cost ratio measures the proportion of conversion costs to the total manufacturing cost, providing valuable insights into the efficiency and cost-effectiveness of the production process. Identify the direct labor and manufacturing overhead costs for a given period. Direct labor costs are the wages and benefits paid to the workers who directly work on the product. Manufacturing overhead costs are the indirect costs that support the production process, such as utilities, rent, depreciation, maintenance, etc.

Operations managers use conversion costs to help identify waste within the manufacturing process. It is easier to track the materials and conversion costs for one batch and have those costs follow the batch to the next process. Direct labor costs are the wages and salaries paid to employees who are directly involved in the production process. This includes assembly line workers, machine operators, and other staff who work directly on manufacturing the product. By using conversion costs, we can calculate an efficient way of determining equivalent units and unit costs. In this section, we will delve into the topic of conversion cost efficiency and explore strategies to enhance the conversion process while minimizing costs.

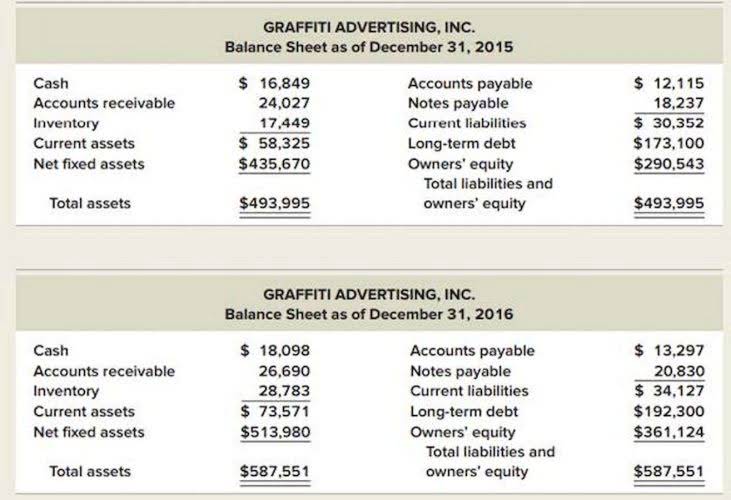

The inventory valuation is the cost of the goods that are not sold and remain in the ending inventory, and it is reported as a current asset in the balance sheet. The conversion cost affects both the COGS and the inventory valuation, depending on the method used to calculate it. The weighted average method assigns the same conversion cost per unit to both the COGS and the inventory valuation. The FIFO method assigns a lower conversion cost per unit to the COGS and a higher conversion cost per unit to the inventory valuation.

Prime costs and conversion costs include some of the same factors of production expenses, but each provides a different perspective when it comes to evaluating production efficiency. A company’s accounts managers and production managers calculate these conversion costs to estimate the production expenses, and the value of the finished and unfinished inventory, and make product-pricing models. Conversion cost is the cost incurred by any manufacturing entity in converting its raw material into finished goods capable of being sold in the market. It usually includes the total value of labor cost and other applied overheads like factory overheads, administrative overheads, etc. As can be seen, labor is the cost that mainly determines the transformation or conversion process, then from here on there must be costs of a similar nature or of a similar impact.

Remember that you can define conversion however you want, such as total conversion costs the number of sales and number of operating leverage dol formula + calculator signups for your email list. The following are some of the most commonly used conversion metrics when assessing conversion cost. Each has its own example of how you would assess conversions with your given definition for the conversions.

Conversion cost is a useful tool for cost accounting and management, and it can help to improve the performance and profitability of any business. ABC International incurs a total of $50,000 during March in direct labor and related costs, as well as $86,000 in factory overhead costs. Therefore, Bookkeeping for Veterinarians the conversion cost per unit for the month was $6.80 per unit (calculated as $136,000 of total conversion costs divided by the 20,000 units produced).

This report shows the costs used in the preparation of a product, including the cost per unit for materials and conversion costs, and the amount of work in process and finished goods inventory. A complete production cost report for the shaping department is illustrated in Figure 5.6. In addition to the equivalent units, it is necessary to track the units completed as well as the units remaining in ending inventory. A similar process is used to account for the costs completed and transferred. recording transactions Direct labor costs are a critical component of conversion costs, representing the wages and benefits paid to workers directly engaged in the production process.